Introduction to Ship Automation

Ship automation represents a pivotal advancement in the maritime industry, fundamentally transforming how vessels operate. The integration of automated systems plays a crucial role in modern maritime operations, allowing for improved efficiency and safety levels that are increasingly necessary in today’s fast-paced environment. Automation significantly reduces reliance on manual processes, thereby minimizing the possibility of human error, which has long been a concern in maritime navigation and management.

By adopting ship automation, fleet operators benefit from enhanced operational capabilities. Automated systems are designed to control vital instruments and processes, ranging from navigation to engine management. For instance, autonomous navigation systems can automatically adjust a ship’s course based on real-time environmental data, thus improving fuel efficiency and operational costs. This proactive approach not only enhances performance but also contributes to environmental sustainability by reducing a vessel’s carbon footprint through optimized fuel usage.

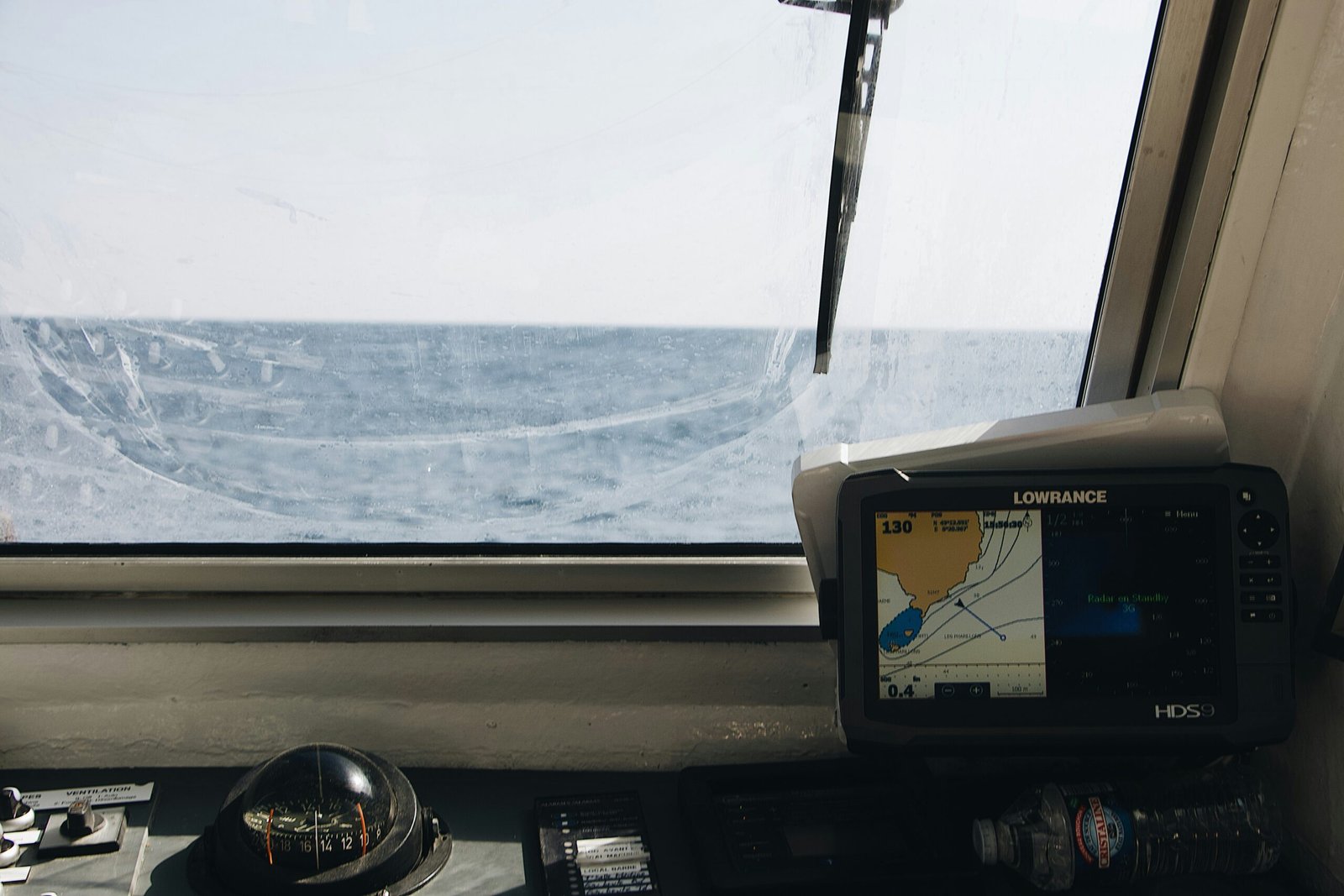

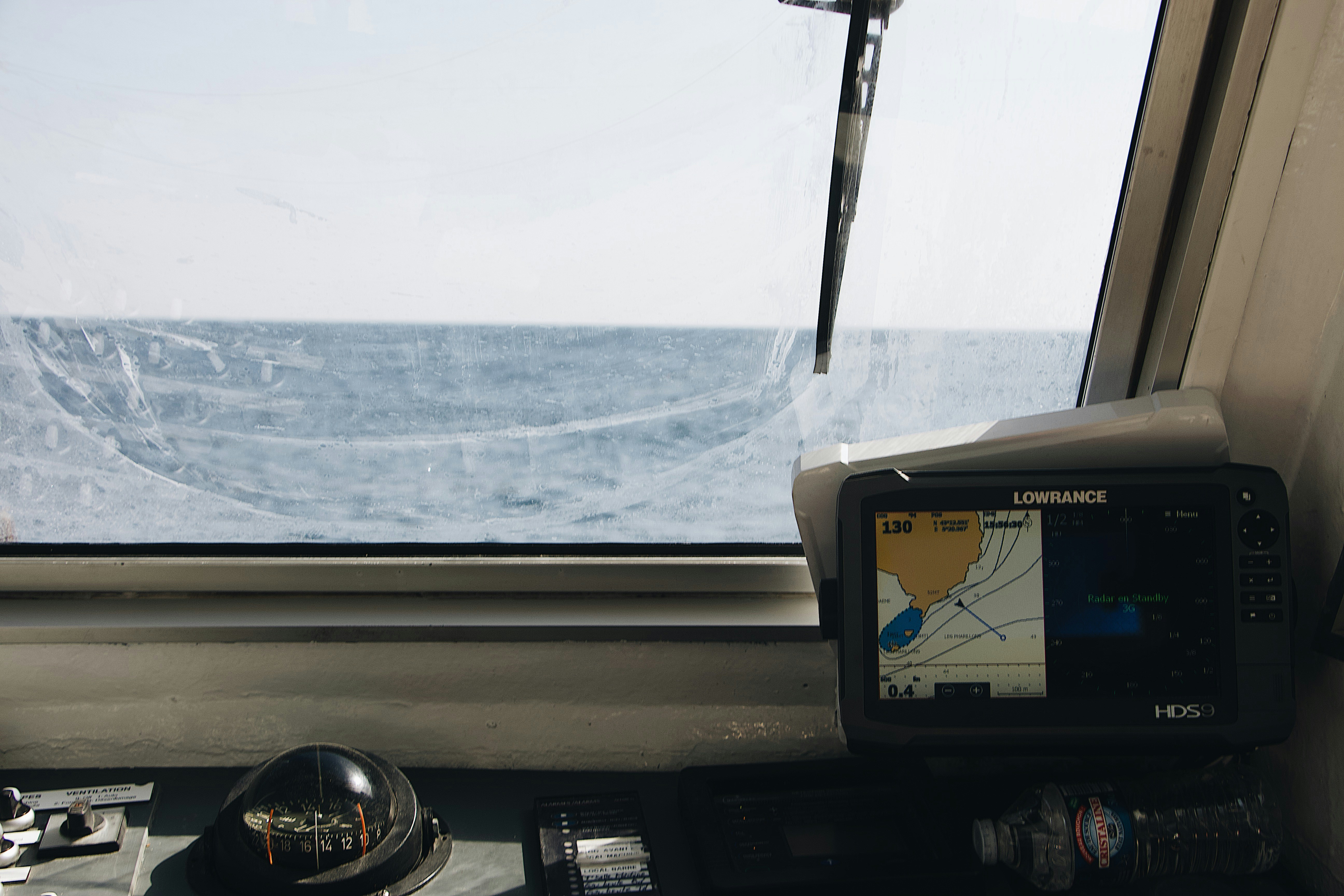

There are several types of automation systems employed in the maritime sector. First, there are systems specific to navigation and positioning, such as Automatic Identification Systems (AIS) and Global Positioning Systems (GPS), which are essential for safe maneuvering. Second, engine monitoring and control systems allow operators to track performance metrics in real-time, enabling predictive maintenance strategies that are vital for avoiding costly breakdowns. Marine automation spare parts—including sensors, control units, and actuators—are crucial in ensuring these systems function optimally.

Further, marine electronics spare parts contribute significantly to the seamless operation of these automation systems. In a sector where reliability is paramount, maintaining the integrity and functionality of these components is essential. Understanding the components involved in ship automation lays the groundwork for recognizing their importance and necessitates adequate investment in marine spare parts to ensure operational efficiency and risk mitigation in maritime ventures.

Essential Marine Electronics and Spare Parts

Marine automation is a critical aspect of modern shipping, significantly enhancing efficiency and safety. Central to this system are various types of marine electronics, which help ensure seamless operations on board. Key components include navigation systems, communication devices, and engine control systems. Each of these elements plays an integral role in the overall function of a vessel, providing essential data and control mechanisms necessary for successful maritime operations.

Navigation systems are foundational, enabling vessels to plot their courses accurately. These systems utilize GPS, radar, and other technologies to facilitate safe and efficient navigation, reducing the risk of mishaps. Similarly, communication devices are crucial for maintaining contact with other ships and shore stations, ensuring that information is shared promptly and effectively. Together, these systems work in tandem to safeguard maritime operations.

In conjunction with these essential electronic components, marine automation systems rely on a robust supply of spare parts to ensure ongoing functionality. Regular maintenance of marine electronics is vital, as the consequences of equipment failure can be severe. A lack of reliable marine spare parts may lead to unplanned downtime, costly delays, and potentially hazardous situations at sea. Consequently, operators must prioritize maintaining an inventory of high-quality marine automation spare parts to mitigate risks.

When selecting spare parts, it is important to source from trusted suppliers who offer verified marine electronics spare parts. Companies that specialize in marine environments will often provide parts that meet industry standards, ensuring the safety and reliability of the equipment. Regularly assessing inventory levels, understanding the specific requirements of onboard systems, and forming partnerships with reputable providers are key strategies for maintaining operational integrity. Doing so not only enhances safety but also promotes the longevity of marine electronics, reinforcing the importance of diligent maintenance procedures.

Benefits of Investing in High-Quality Spare Parts

Investing in high-quality marine automation spare parts and marine electronics spare parts is critical for ensuring the longevity and reliability of automated systems onboard vessels. Quality spare parts provide greater durability and performance, ultimately leading to enhanced efficiency on maritime operations. The operational environment that vessels encounter is often harsh and demanding; thus, using superior components significantly reduces the risk of unexpected breakdowns and malfunctions.

One notable benefit of utilizing high-quality marine spare parts is cost-effectiveness over time. While the initial investment may be higher than that of cheaper alternatives, it is essential to recognize the long-term savings that quality components afford. For instance, subpar parts may lead to frequent repairs and replacements, incurring additional costs and extended downtime. In contrast, reliable marine automation spare parts often come with warranties and greater longevity, which translates to less disruption in operations and better overall productivity.

To illustrate this point, consider a case study from a shipping company that chose high-quality marine electronics spare parts for their navigation systems. Over five years, they experienced significantly fewer system failures compared to competitors that opted for lower-cost options. This foresight allowed them to maintain their schedules, resulting in improved customer satisfaction and ultimately higher revenue. Another example involves a vessel that upgraded its automated engine control systems with premium marine spare parts, leading to enhanced fuel efficiency and reduced operational costs, solidifying the argument that high-quality components are an investment in sustained performance.

Investing in high-quality marine automation and electronics parts is not only a proactive step towards maintaining equipment integrity but also a strategic decision that yields long-term financial benefits. By prioritizing quality, operators can safeguard their operations while enhancing the reliability of their maritime technologies.

The Future of Ship Automation: Trends and Innovations

As the maritime industry continues to evolve, the integration of advanced technologies into ship automation systems is becoming increasingly significant. Emerging trends, particularly in artificial intelligence (AI), the Internet of Things (IoT), and predictive maintenance, are driving a transformation in maritime operations and supply chains for marine spare parts.

Artificial intelligence is poised to revolutionize ship automation by enabling vessels to make data-driven decisions. AI-driven systems can analyze vast amounts of data generated during voyages and optimize route planning, fuel consumption, and overall operational efficiency. This advancement not only enhances performance but also reduces the need for certain marine spare parts, as operational efficiencies lower wear and tear, extending the lifespan of existing components.

Moreover, the Internet of Things is facilitating unprecedented connectivity in maritime operations. Sensors connected to a central system keep track of various parameters such as maintenance levels, performance metrics, and environmental conditions. This real-time data collection offers valuable insights that can lead to proactive maintenance and timely replacement of marine electronics spare parts. This connectivity ensures that vessels remain compliant with regulatory standards, reducing the risk of downtime and costly repairs.

Predictive maintenance technologies further enhance the operational capability of vessels. By leveraging machine learning algorithms and historical data, ship operators can predict when a component is likely to fail, allowing for timely interventions before issues escalate. This approach not only reduces the operational impact of failures but also optimizes the procurement cycle for marine automation spare parts, ensuring they are sourced and supplied as needed without excess inventory costs.

In this rapidly evolving landscape, it is essential for maritime stakeholders to stay informed about these advancements. Understanding the implications of innovations in ship automation and the associated marine spare parts can lead to improved efficiency, streamlined supply chains, and ultimately, a more competitive maritime industry.